Technical Information

Solid square shaft piles — The traditional solid shaft pile. ASTM A29 material

1.50” shaft— 27.5 KIP design/55 KIP Ultimate capacity.

Typically, can offer the higher capacity 2 7/8” round pile for practically the same cost.

1.75” shaft— 50 KIP Design/100 KIP Ultimate Capacity

Typically, slightly more expensive than the 3” square pile and has lower capacity.

Tubular helical pile options – listed in order of increasing capacity.

2 3/8” round Piles — Lowest cost material per pile. Commonly used for underpinning applications. Can be used for any application with light loads.

0.190” wall API 5CT mat’l

Compression Loads: 22.5 kip design/45 kip ultimate capacity

Tension Loads:

2 7/8” round certified Piles — Certified to meet International Building Code requirements. Certified in ICC Report ESR-4050. Typically used when a certified pile is called out in architect or engineer specifications.

0.276” wall ASTM A500 mat’l —

Compression Loads: 36 kip design/72 kip ultimate capacity

Tension Loads: 29 kip design/59 kip ultimate

2 7/8” round Piles — Stronger and cheaper than the 2 7/8” certified pile. Can be the best choice when pile capacities between 20 – 42 kip design are needed. Has a higher tension capacity than the 3” square pile so likely the most economical choice in tension applications.

0.217” wall API 5CT mat’l—

Compression Loads: 42.5 kip design/85 kip ultimate capacity

Tension Loads: 29 KIP design/59 kip ultimate

3 1/2” round certified Piles — Certified to meet International Building Code requirements. Certified in ICC Report ESR-4050. Typically used when a certified pile is called out by architect or engineer specifications and higher capacity pile than the 2 7/8” is needed. Only slightly higher capacity than the 2 7/8” API 5CT pile, but significantly higher material cost.

0.300” wall ASTM A500 mat’l

Compression Loads: 43.4 kip design/86.8 kip ultimate capacity

Tension Loads: 43 kip design/87 kip ultimate capacity

3 1/2” round Piles — When round piles are preferred and loads are more than can be handled by 2 7/8” piles. Comparable compression capacity to the 3” square pile, but higher tension capacity. It takes larger equipment and time to install than the square pile.

0.254” wall API 5C mat’l—

Compression Loads: 54.2 kip design/108.5 kip ultimate capacity

Tension Loads: 43 kip design/86.8 kip ultimate Capacity

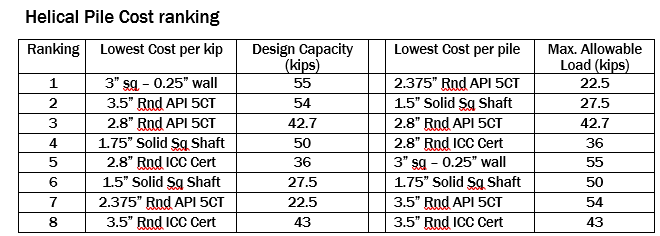

3” Square Piles — Our most economical option when piles can be loaded to capacity. Lowest cost per kip of capacity. Quickest install times. Common configurations are stocked and normally has a shorter lead time for delivery.

Lowest cost pile per kip of capacity

Lowest cost pile when allowable loads >42.7 kip are required

0.250” wall A500 mat’l

Compression Loads: 55 kip design/110 kip ultimate

Tension Loads: 25 kip design/50 kip ultimate

Note 1: Cost per kip ranking based on a hypothetical design load of 1,650 kips and all piles installed to 35’ depth.

Note 2: Cost per pile ranking based on hypothetical case of 30 piles installed to 35’ depth.